By Keith H.

My big project this year is to get a DEC 340 monitor working. Here is a picture of one of them.

.jpg.aspx)

The DEC 340 was a very early and rare computer monitor dating from the mid 60’s used of course, on DEC computers, their PDP series. Two cabinets of rack mounted electronics. The 340 is historic and was used in some early work that pioneered modern computer graphic techniques. It is quite a bit different from Cathode Ray Tube (CRT) monitors used by personal computers we were all familiar with a few years ago. In comparison it is alien technology. All circuits are implemented using discrete components and there are no integrated circuits anywhere in the design. The discrete components themselves are unusual dating from the early days of transistor use.

The DEC 340 I have to work on is missing the cabinet on the right. It seems to have been lost in the sands of time. The cabinet with the big tube on the left is the one we have. It is covered inside and out by a thin layer of rouge desert dust. A peek inside the cabinet and the dust suggests our DEC 340 could have crashed onto the desert outside Roswell, New Mexico as part of a flying saucer or come from the surface of Mars as alien technology. My peek inside had looked strange, alien. It took me a few moments to understand what I had seen. Then I had an a-ha moment. I realized this is how DEC computer engineers of the time did analog electronics. Everything is packaged the same way discrete digital circuits of the day were, as digital circuits of the time had to be connected together because of their complexity and size. Circuit cards of components in racks of connectors connected to back-planes carried buses of signals in digital circuits but analog signals may not like the same kind of connections as digital connections do. They may require different considerations. I’m not used to seeing analog signals jumping from place to place as if electronic noise did not matter.

I can’t be critical because DEC 340 analog electronics obviously worked, but path length is usually kept short when making analog connections. This keeps noise pick up to a minimum and signals clean. I was surprised by what I saw in the 340 but DEC did not make radios or TVs. DEC built computers and I figure their engineers had to do things a certain way. Maybe even if they knew better. The layout which to me looks odd must have made somebody happy. Having all the electronics which connect to the CRT at least be in the same cabinet seems to have been the only concession made to analog design considerations but since it worked that’s OK. Scrounging for documentation I found that DEC had used the same CRT in other monitors and essentially the same drive electronics on the tube itself, so whatever problems they had only needed to be solved once. That was a good discovery, some of that documentation helps me out.

Our 340 is incomplete with parts missing and actually came from a junkyard in Australia where it had been sitting outside for a while. Arid conditions somewhat preserved this DEC 340 but sadly it is incomplete. Our 340 is a carcass of missing pieces and this incompleteness enhances the feeling it is something from another world. Original components to build up missing circuit boards and for repair of circuits we have can not all be found. Old components are often not made of the materials modern components are and sometimes they do not age well. Arid also does not mean it is always dry.

We have the magnetic deflection yoke and tube. Essential parts which I can’t re-manufacture.

.png.aspx) The Sixteen Inch Radar Tube

The Sixteen Inch Radar Tube

But an entire cabinet of components is missing. Racks of digital circuit cards which made the DEC 340 a processing device all on its own. Circuits which offloaded details of drawing from the host computer to which it was attached to lighten the host processing load. For these circuits we have only paper documentation. Output from the missing circuits drove circuits which controlled a big round sixteen inch radar CRT around which the DEC 340 was built. These circuits I have because they are analog circuits that were mounted close to the display CRT to minimize electrical interference. These circuits were in the same cabinet as the CRT; the only cabinet we have. Within the cabinet the analog circuits were implemented using Digital Equipment System Building Block technology where space allowed.

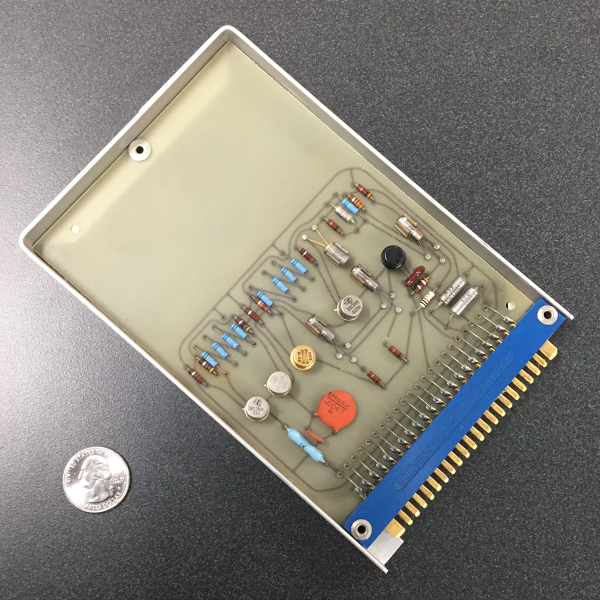

System Building Blocks, are circuit boards mounting discrete components with a heavy duty 22 pin gold plated connector on one end to create a ‘block’ that can be used to build a ‘system’. The three sides without the connector are wrapped by an aluminum band. System Building Blocks plugged into a rack mount which could hold up to 25 blocks. Twenty five side by side connectors were interconnected on each rack mount to create a back-plane which resembled the way typical computer circuits of the day were implemented. That resemblance aside, System Building Blocks implemented both analog and digital circuits in implementations which today would be called ‘mixed signal’. Here is one of our modules with dust gently brushed off and blown away by compressed air.

A 1575 System Building Block

A 1575 System Building Block

The transistors and diodes used in these circuits became obsolete long ago. Some were made of germanium which was only used as a semiconductor material in the early years of semiconductor electronics. Silicon is used almost exclusively as a semiconductor now. Silicon is a superior semiconductor for common uses, but in the early days of transistors. Germanium was a semiconductor of choice. Techniques for working with silicon had yet to be perfected. I can get vintage germanium parts but they are expensive and hard to find. The numbers on the silicon transistors used I have not seen before. The vacuum tube era had just come to an end when the DEC 340 was built. Transistors were new and the ones used in the DEC 340 became quickly obsolete and are uncommon.

I would have to pay a lot for replacements, those I could find. There are vendors who specialize in old parts. They don’t have everything. I would have a great deal of problems replacing components with original parts or parts with even similar specifications. Diodes this old when put on a curve tracer can sometimes look more like a resistor than a diode. Gray corrosion coats component leads. I am concerned about the diodes and transistors which have leads that were not gold plated. The hermetic seal on some of those components is sure to have failed. The plating on the steel rack which holds the circuit cards shows spots of corrosion documenting that condensation has visited the components.

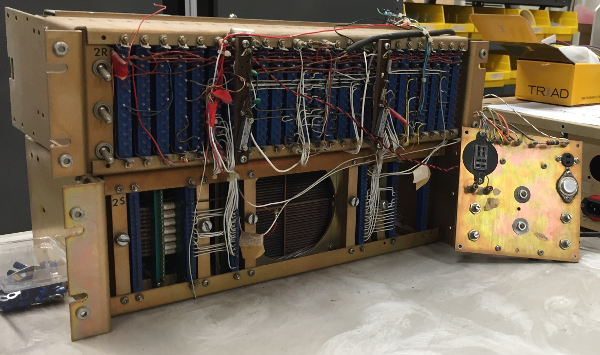

I only have one rack of circuit cards that contain System Building Block cards like that shown above. These circuits control to the CRT. All of the other electronics are missing. An entire cabinet full of card racks. All the signals to the cards I do have came from this second cabinet of cards that I only have paper documentation for. A second rack mounted below the first was cooled by forced air and is show here. The components on this rack are part of System Building Block schematics with components too big and which ran too hot to be mounted onto System Building Block circuit cards in a rack that takes thin plug in cards mounted side by side. Shown here are these two rack mounts removed from the cabinet they came in. A patch panel which jumped wires to the CRT from these racks is also shown. It was mounted in space inside the cabinet behind the racks and holds components on the other side.

The Electronic Carcass (removed from rack)

The Electronic Carcass (removed from rack)

So what to do? My first decision upon reviewing the documentation and physical parts I had was to decide to reproduce the electronic circuits using modern components on new circuit cards. I might enjoy getting the original electronic circuits working but it is too risky and I do not have them all to begin with. I look at the glass diodes on the circuit cards and cringe. I don’t trust any of them. They have experienced morning dew and have corroded. We already know that the glass seal on old diodes can fail with time and a desert is not needed for that. Even if the diodes work I’d not trust them to keep working for long. Working on stuff knowing replacements are not available is scary. I would not want to plug in a one of a kind circuit and see smoke. I also know that the traces on circuit boards this old lift very easy so it is easy to damage these circuit boards when changing components. Even a little heat can turn circuit boards this old brown and lift traces.

Reproducing the function of all the original circuits seems my best path. I located schematics for all the circuits so I can understand how they work and work together. My goal is to get the big radar tube working as it once did. Accomplishing that task using modern components based on original schematics will be fine and if something burns up I can replace it. Had the whole 340 made it to the desert to be found I might have decided to get the old circuits working and scramble for parts but with half our 340 missing, building all the electronics from scratch seems the best way to go for my best chance of success. That the DEC System Building Blocks were made using a proprietary connector has no small influence on my decision. I can create work alike versions using printed circuit cards which plug into easily obtained edge connectors but mixing and matching that arrangement just to accommodate the few System Building Blocks I do have makes no sense at all. It will be far easier to rebuild everything around a common connector that I can get than to rebuild the back plane using half new and half old parts which are actually incompatible in physical size to begin with.

Another consideration is the issue of interface. The original System Building Block circuits interfaced to DEC equipment logic levels which range from ground to a negative voltage. We will be implementing the DEC 340 logic functions using modern technology which uses logic of a positive voltage, so I need equivalent System Building Blocks which interface to positive voltage. None exist, the only way I am going to get those is if I make them. A level of voltage translation circuitry between existing cards might cause timing problems best avoided. Another reason not to use the cards I have but to make work alike copies is the extra work of translating voltages cancels out the cost and work of reproducing circuits with voltage translation built in. As will be explained in basic operation, for its time, the DEC 340 was a high performance device and I must pay close attention to timing requirements.

Will it really be a DEC 340? Yes it will. The tube will be original or an original replacement (I found one at a surplus store) and the deflection coil, which drove the tube, will be original as there are no replacements for that anywhere to be found. Function of the original DEC 340 will be achieved in a work alike reproduction driving an original tube. The electronics will reproduce the function of the original and if parts fail, replacements will be available.

This article introduces my big project for the year but I have been working on it for a while. I have been creating schematics of the circuits I need and have been planning how it all goes together. I have been buying parts I know I will use. My original plan with this blog post was to write about the circuit on the 1575 System Building Block I show above. It is a fascinating and interesting circuit that I had to understand in great detail to implement right. I can base my circuits on original circuit topology and honor the basic method and forms but using new components with characteristics that don’t match exactly means I have to check that all the math works out right. This changes the values on some resistors and capacitors, so components are biased correctly. I simulate the circuits in a circuit analysis program so they have the best chance of working without needing later adjustments after I build them.

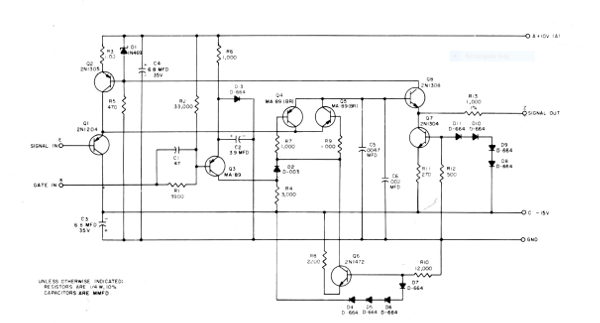

I could not write about the 1575 System Building Block circuit without introducing my project. I still need to describe the basic operation of the DEC 340 before discussing the operation and function of the 1575 circuit. Understanding a circuit is a lot more fun if you know what it is used for. I find it can make the difference between being fascinating and boring, though the 1575 circuit is fascinating on its own. In my next blog post I’ll describe basic operation of the DEC 340. Eventually I will explain what Q4 and Q5 do in the 1575 circuit. They are in the center of the below schematic.

1575 System Building Block Schematic

1575 System Building Block Schematic

In the original circuit they are germanium transistors in a place where germanium seems to actually be a better circuit choice as will be explained. It is an unusual circuit I have only seen a few times in my life and the way it works is subtle. It is used to switch a voltage under very specific requirements. It is fascinating because it seems to work better than it should and some thought on transistor physics is needed to understand why. I will be implementing two missing DEC 340 Digital to Analog converters and a 1575 type circuit takes the voltages produced by these D to A converters to feed downstream amplifiers. But first I’ll describe the basic operation of the DEC 340 and how it differs from the later computer monitors which became the mainstream standard for many years.